Collections Item Detail

Article: Rapid Erection of Pier Shed Frame, D.L.& W. R.R.; Engineering News, Vol. LIV, No. 12, Sept. 21, 1905.

2010.007.0210

2010.007

Lukacs, Claire

Gift

Museum Collections. Gift of a friend of the Museum.

1905 - 1905

Date(s) Created: 1905 Date(s): 1905

Good

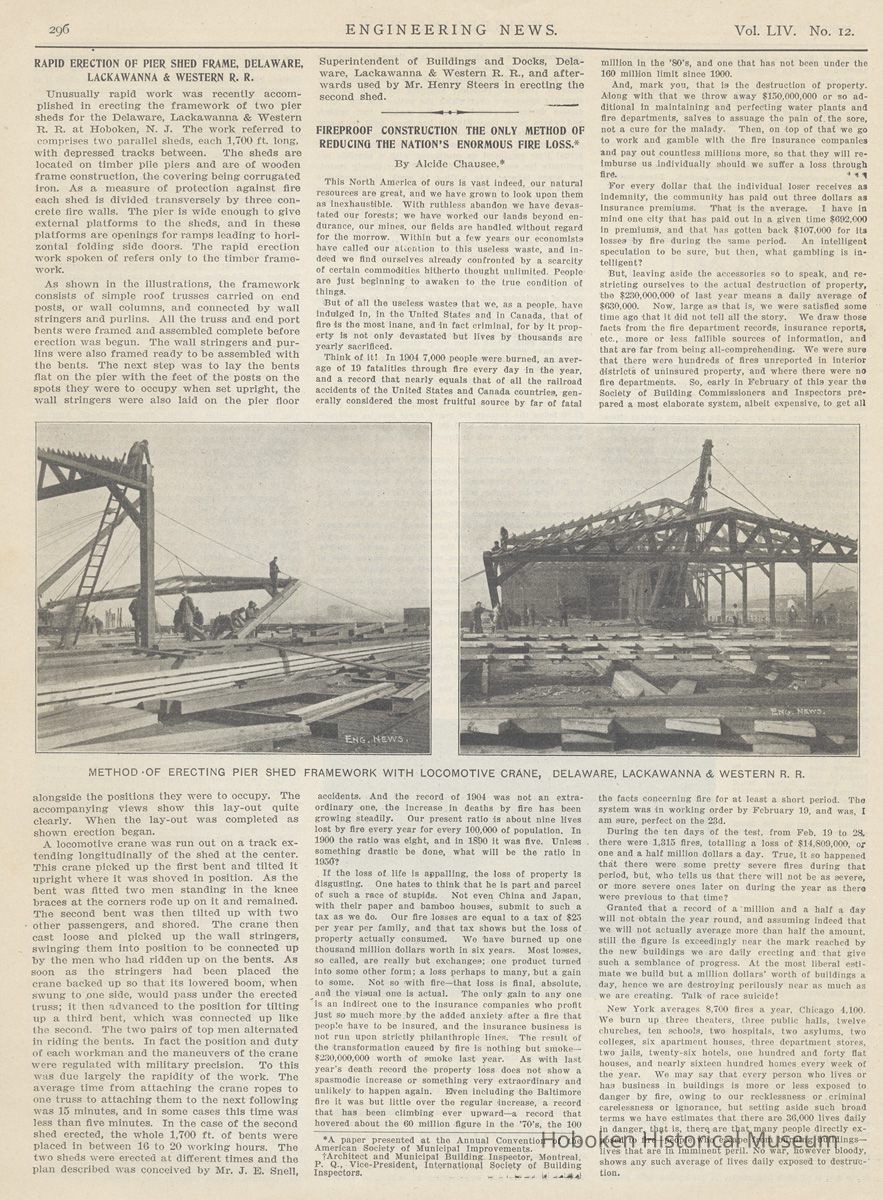

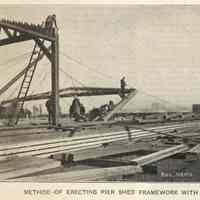

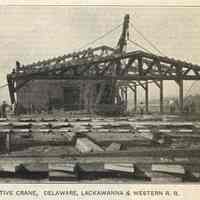

Notes: Transcription of article on page 296, column 1 of Engineering News, Vol. LIV, No. 12, Sept. 21, 1905. Archives 2010.007.0210. RAPID ERECTION OF PIER SHED FRAME, DELAWARE, LACKAWANNA & WESTERN R. R. Unusually rapid work was recently accomplished in erecting the framework of two pier sheds for the Delaware, Lackawanna & Western R. R. at Hoboken, N. J. The work referred to comprises two parallel sheds, each 1,700 ft. long, with depressed tracks between. The sheds are located on timber pile piers and are of wooden frame construction, the covering being corrugated iron. As a measure of protection against Are each shed is divided transversely by three concrete fire walls. The pier is wide enough to give external platforms to the sheds, and in these platforms are openings for ramps leading to horizontal folding side doors. The rapid erection work spoken of refers only to the timber framework. As shown in the illustrations, the framework consists of simple roof trusses carried on end posts, or wall columns, and connected by wall stringers and purlins. All the truss and end port bents were framed and assembled complete before erection was begun. The wall stringers and purlins were also framed ready to be assembled with the bents. The next step was to lay the bents flat on the pier with the feet of the posts on the spots they were to occupy when set upright, the wall stringers were also laid on the pier floor alongside the positions they were to occupy. The accompanying views show this lay-out quite clearly. When the lay-out was completed as shown erection began. A locomotive crane was run out on a track extending longitudinally of the shed at the center. This crane picked up the first bent and tilted it upright where it was shoved in position. As the bent was fitted two men standing in the knee braces at the corners rode up on it and remained. The second bent was then tilted up with two other passengers, and shored. The crane then cast loose and picked up the wall stringers, swinging them into position to be connected up by the men who had ridden up on the bents. As soon as the stringers had been placed the crane backed up so that its lowered boom, when swung to one side, would pass under the erected truss; it then advanced to the position for tilting up a third bent, which was connected up like the second. The two pairs of top men alternated in riding the bents. In fact the position and duty of each workman and the maneuvers of the crane were regulated with military precision. To this was due largely the rapidity of the work. The average time from attaching the crane ropes to one truss to attaching them to the next following was 15 minutes, and in some cases this time was less than five minutes. In the case of the second shed erected, the whole 1,700 ft. of bents were placed in between 16 to 20 working hours. The two sheds were erected at different times and the plan described was conceived by Mr. J. E. Snell, Superintendent of Buildings and Docks, Delaware, Lackawanna & Western R.R. and afterwards used by Mr. Henry Steers in erecting the second shed. [caption for two photos across center of page: METHOD OF ERECTING PIER SHED FRAMEWORK WITH LOCOMOTIVE CRANE, DELAWARE, LACKAWANNA & WESTERN R.R.] Status: OK Status By: dw Status Date: 2010-10-19