Collections Item Detail

Article [Holland Tunnel]: Linking New York and New Jersey. By Clifford M. Holland; in The American City, Vol. XXIV, no. 3, March 1921.

2011.005.0068

2011.005

Lukacs, Claire

Gift

Museum Collections. Gift of a friend of the Museum.

1921 - 1921

Date(s) Created: 1921 Date(s): 1921

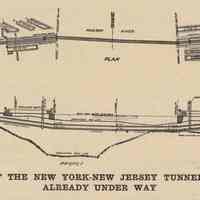

Notes: archives 2011.005.0068 (article published in The American City, Vol. XXIV, No. 3, March 1921, pp. 231-232) 231 Linking New York and New Jersey The Isolation of these Two States from Each Other to be Overcome by New Vehicle Tunnels By Clifford M. Holland Chief Engineer, New York and New Jersey Tunnel Commission THE states of New York and New Jer- sey, which are vitally interdependent, have needed for many years a larger and more reliable link in their transporta- tion facilities than the present overburdened ferry system. There is no room for the ex- pansion of the existing ferry service, and the transportation business of the water- front has vastly outgrown its present facil- ities. To overcome this lack of transporta- tion the new interstate tunnel was proposed and is now actually under construction. Although the total cost of the undertaking is estimated at $28,669,000, it has been shown that with reasonable tolls the tunnel will not only pay its maintenance but within [illustration] PROFILE AND PLAN OF THE NEW YORK-NEW JERSEY TUNNEL, WORK ON WHICH IS ALREADY UNDER WAY 12 years will pay its entire cost of construc- tion, and by the end of 20 years there will be a surplus of more than $66,000,000 to be divided between the states of New York and New Jersey. The essential features of the proposition are the construction of twin tubes of cast iron, 29 feet in external diameter, larger than any existing American sub-aqueous tunnel of the shield-driven type. The mean length of the cast iron ring section will be 6,600 feet, and the distance between grade points of the tunnel-which includes the open-cut approaches-is 9,300 feet. There are to be two ventilating shafts on each shore to take care of the removal of ob- noxious exhaust gases from motor vehicles. The ventilation problem has been one of the most difficult of solution in connection with the tunnel project. The tunnel will run from Canal Street, New York, a wide east-and-west thorough- fare which is approximately at the center of down-town traffic over the Hudson fer- ries, to a point almost directly opposite on the New Jersey shore, thus giving a tunnel of minimum length. The New Jersey ter- minus is near the center of traffic and af- fords direct communication with Jersey City Heights and points beyond, and the water- front and railroad yards are easily accessible. In determining the traffic capacity of the tunnel, the chief considerations were: (1) volume and character of the vehicular traf- fic which will seek the tunnel; (2) capacity of one, two and three lines of traffic in each direction; (3) economical size of tunnel in relation to amount of traffic; (4) limitation of traffic by street congestion in vicinity of tunnel entrances and exits. A careful study of the average daily traffic based on 24- hour counts made at the ferries was 12.2 times the maximum hourly traffic. A study of conditions showed that a two-line tun- nel-that is, four traffic streams-will have sufficient capacity to accommodate all traf- fic of motor as well as horse-drawn vehicles 232 THE AMERICAN CITY VOL. XXIV, No. 3 up to the year 1935, and if horses were eliminated during rush hours its capacity would not be reached until 1937. To determine the proper dimensions of the tunnel, measurements were taken of vehicles crossing the Hudson River on the ferries between New York and New Jersey, and it was found that their height varied from 6 feet 6 inches for passenger cars to a maxi- mum of 13 feet for large loaded trucks, but that the number exceeding 12 feet in height was not over 1 per cent. It was also found that the width of motor vehicles varied from 6 feet for passenger cars and light trucks to a maximum of 10 feet 6 inches for army transport trucks. In the case of three-horse teams, the outside dimension of three horses abreast was found to be 9 feet, but the num- ber of vehicles exceeding 8 feet in width is only 3J4 per cent. Motor truck manufacturers suggested 12 feet 2 inches as the greatest distance be- tween the road and the top of the truck body, and 8 feet as the greatest width of the body. To provide for all contingencies, such as unevenness in the surface of the roadway, spring action of vehicles, and al- lowances for jacking up in case of break- down, the clear headroom of the tunnel was fixed at 13 feet 6 inches. With the tunnel carrying two lines of vehicles in the same direction on one road- way, the normal operation conditions are as though there were one vehicle 8 feet wide in the slow line, and one 6 feet wide in the fast line. There may be times, however, when there will be 8-foot-wide vehicles op- erating in both the slow line and the fast. In the slow line of the two-line tunnel ve- hicles operating at a speed of 3 to 6 miles per hour should have a clearance of not less than 6 inches between the outside of the tire and the curb, while in the fast line, on account of the greater speed, this clearance should be not less than 1 foot. Allowance is made for a minimum clearance of I foot 9 inches between the moving vehicles, and the minimum width of roadway is 19 feet. For safe and convenient operation, however, a clearance of 2 feet 9 inches between the moving vehicles should be provided, giving a 20-foot width of roadway for two-line traffic, which has been provided. The problem of ventilating the tunnel has been investigated under three main sub- divisions: (1) amount and composition of exhaust gases from motor vehicles; (2) di- lution necessary to render these exhaust gases harmless; (?3) method and equipment necessary for adequate ventilation. After very thorough study the tunnel has been de- signed with four ventilating shafts, two of which, 3,400 feet apart, are located near the pierhead line, and the other two between these shafts and the portals. With this ar- rangement, cost of operation is reduced to about one-quarter of what it would be if the tunnel were provided with only two ventilat- ing shafts at the bulkheads. All fans and motors are to be located in structures at the top of the ventilating shafts, and will be of standard sizes. The fresh-air duct is to be located between the roadways and the ex- haust duct above, in accordance with the results of experiments conducted in 1916 by the Public Service Corporation of New Jersey. Work has already begun in digging the shaft for the tunnel, and contracts are being let gradually, in order to take advantage of the possible reduction in labor and material costs within the next three years. Status: OK Status By: dw Status Date: 2011-04-19