Collections Item Detail

Article: The New Fireproof Piers of the North German Lloyd Steamship Co. at Hoboken; in Engineering News, Vol. XlV, No. 1, Jan 3. 1901.

2011.005.0073

2011.005

Lukacs, Claire

Gift

Museum Collections. Gift of a friend of the Museum.

1901 - 1901

Date(s) Created: 1901 Date(s): 1901

Good

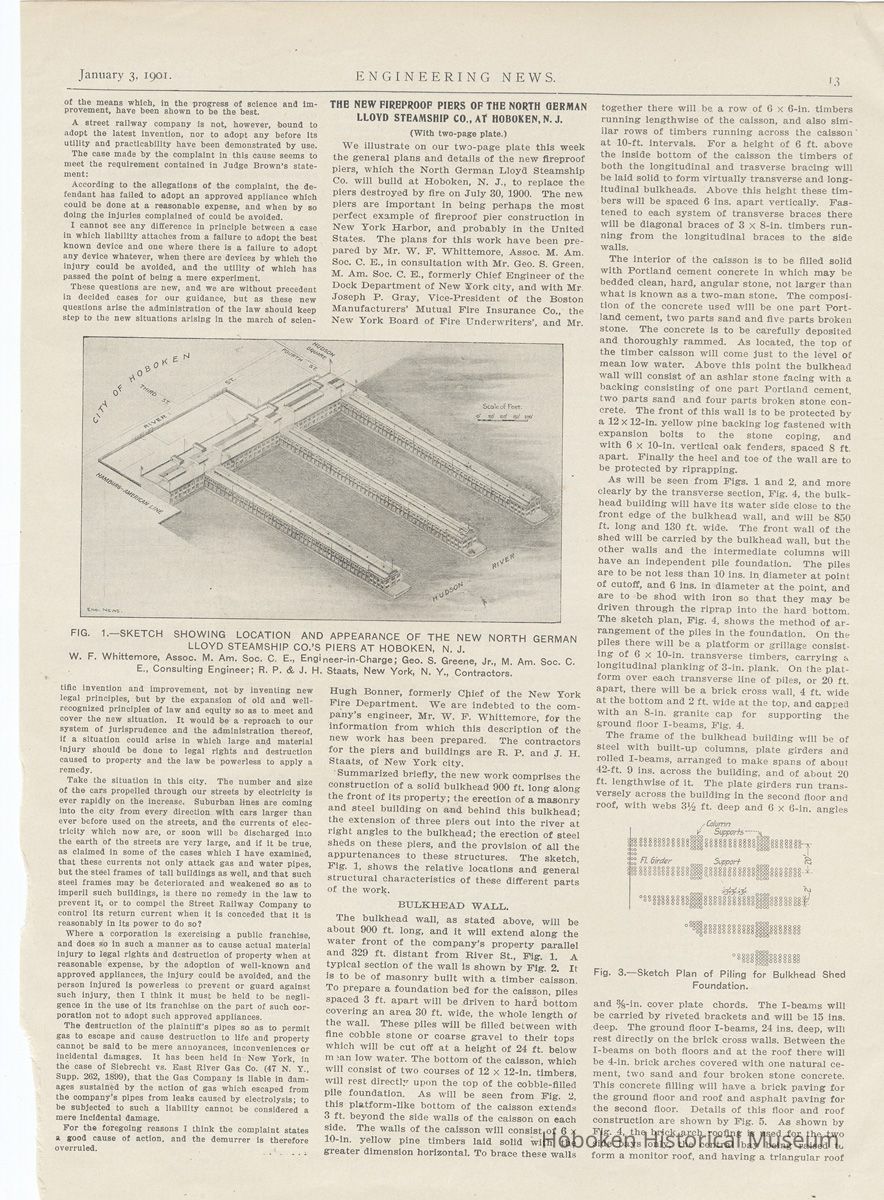

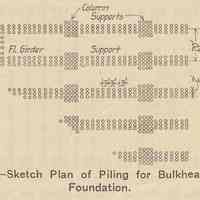

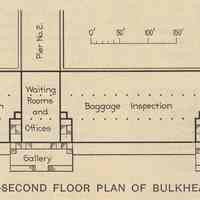

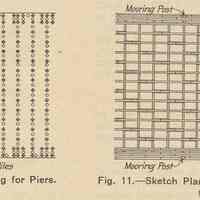

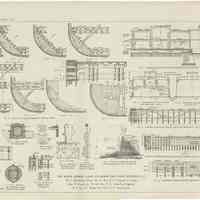

Notes: archives 2011.005.0073 article published in ENGINEERING NEWS, Vol. XlV No. 1, January 3, 1901. THE NEW FIREPROOF PIERS OF THE NORTH GERMAN LLOYD STEAMSHIP CO., AT HOBOKEN, N. J. (With two-page plate.) We illustrate on our two-page plate this week the general plans and details of the new fireproof piers, which the North German Lloyd Steamship Co. will build at Hoboken, N. J. to replace the piers destroyed by fire on July 30, 1900. The new piers are important in being perhaps the most perfect example of fireproof pier construction in New York Harbor, and probably in the United States. The plans for this work have been prepared by Mr. W. F. Whittemore, Assoc. M. Am. Soc. C. E., in consultation with Mr. Geo. S. Green, M. Am. Soc. C. E., formerly Chief Engineer of the Dock Department of New York city, and with Mr. Joseph P. Gray, Vice-President of the Boston Manufacturers' Mutual Fire Insurance Co., the New York Board of Fire Underwriters', and Mr. FIG. 1. — SKETCH SHOWING LOCATION AND APPEARANCE OF THE NEW NORTH GERMAN LLOYD STEAMSHIP CO.'S PIERS AT HOBOKEN, N. J. W. F. Whittemore, Assoc. M. Am. Soc. C. E., Engineer-in-Charge; Geo. S. Greene, Jr., M. Am. Soc. C. E., Consulting Engineer; R. P. & J. H. Staats, New York, N. Y., Contractors. Hugh Bonner, formerly Chief of the New York Fire Department. We are indebted to the company's engineer, Mr. W. F. Whittemore, for the information from which this description of the new work has been prepared. The contractors for the piers and buildings are R. P. and J. H. Staats, of New York city. Summarized briefly, the new work comprises the construction of a solid bulkhead 900 ft. long along the front of its property; the erection of a masonry and steel building on and behind this bulkhead; the extension of three piers out into the river at right angles to the bulkhead; the erection of steel sheds on these piers, and the provision of all the appurtenances to these structures. The sketch, Fig. 1, shows the relative locations and general structural characteristics of these different parts of the work. BULKHEAD WALL. The bulkhead wall, as stated above, will be about 900 ft. long, and it will extend along the water front of the company's property parallel and 329 ft. distant from River St., Fig. 1. A typical section of the wall is shown by Fig. 2. It is to be of masonry built with a timber caisson. To prepare a foundation bed for the caisson, piles spaced 3 ft. apart will be driven to hard bottom covering an area 30 ft. wide, the whole length of the wall. These piles will be filled between with fine cobble stone or coarse gravel to their tops which will be cut off at a height of 24 ft. below mean low water. The bottom of the caisson, which will consist of two courses of 12 x 12-in. timbers, will rest directly upon the top of the cobble-filled pile foundation. As will be seen from Fig. 2, this platform-like bottom of the caisson extends 3 ft. beyond the side walls of the caisson on each side. The walls of the caisson will consist of 6 x 10-in. yellow pine timbers laid solid with the greater dimension horizontal. To brace these walls together there will be a row of 6 x 6-in. timbers running lengthwise of the caisson, and also similar rows of timbers running across the caisson at 10-ft. intervals. For a height of 6 ft. above the inside bottom of the caisson the timbers of both the longitudinal and trasverse bracing will be laid solid to form virtually transverse and longitudinal bulkheads. Above this height these timbers will be spaced 6 ins. apart vertically. Fastened to each system of transverse braces there will be diagonal braces of 3 x 8-in. timbers running from the longitudinal braces to the side walls. The interior of the caisson is to be filled solid with Portland cement concrete in which may be bedded clean, hard, angular stone, not larger than what is known as a two-man stone. The composition of the concrete used will be one part Portland cement, two parts sand and five parts broken stone. The concrete is to be carefully deposited and thoroughly rammed. As located, the top of the timber caisson will come just to the level of mean low water. Above this point the bulkhead wall will consist of an ashlar stone facing with a backing consisting of one part Portland cement, two parts sand and four parts broken stone concrete. The front of this wall is to be protected by a 12 x 12-in. yellow pine backing log fastened with expansion bolts to the stone coping, and with 6 x 10-in. vertical oak fenders, spaced 8 ft. apart. Finally the heel and toe of the wall are to be protected by riprapping. As will be seen from Figs. 1 and 2, and more clearly by the transverse section, Fig. 4, the bulkhead building will have its water side close to the front edge of the bulkhead wall, and will be 850 ft. long and 130 ft. wide. The front wall of the shed will be carried by the bulkhead wall, but the other walls and the intermediate columns will have an independent pile foundation. The piles are to be not less than 10 ins. in diameter at point of cutoff, and 6 ins. in diameter at the point, and are to be shod with iron so that they may be driven through the riprap into the hard bottom. The sketch plan, Fig. 4, shows the method of arrangement of the piles in the foundation. On the piles there will be a platform or grillage consisting of 6 x 10-in. transverse timbers, carrying a longitudinal planking of 3-in. plank. On the platform over each transverse line of piles, or 20 ft. apart, there will be a brick cross wall, 4 ft. wide at the bottom and 2 ft. wide at the top, and capped with an 8-in. granite cap for supporting the ground floor I-beams, Fig. 4. The frame of the bulkhead building will be of steel with built-up columns, plate girders and rolled I-beams, arranged to make spans of about 42-ft. 9 ins. across the building, and of about 20 ft. lengthwise of it. The plate girders run transversely across the building in the second floor and roof, with webs 3 1/2 ft. deep and 6 x 6-in. angles Fig. 3. — Sketch Plan of Piling for Bulkhead Shed Foundation. and 3/8-in. cover plate chords. The I-beams will be carried by riveted brackets and will be 15 ins. deep. The ground floor I-beams, 24 ins. deep, will rest directly on the brick cross walls. Between the I-beams on both floors and at the roof there will be 4-in. brick arches covered with one natural cement, two sand and four broken stone concrete. This concrete filling will have a brick paving for the ground floor and roof and asphalt paving for the second floor. Details of this floor and roof construction are shown by Fig. 5. As shown by Fig. 4, the brick arch roofing is used for the two side bays only, the central bay being raised to form a monitor roof, and having a triangular roof trussing carrying a roofing of 3-in. plank covered with five-ply felt and gravel covering. The exterior walls of the building are to be of brick laid in Portland cement mortar to a height of 4 ft. above the ground floor and in natural cement mortar for the remainder of the height. The interior columns of the building are to be protected from fire by a concrete casing cons true led as shown by Fig. 6. Transverse fire walls, with double doors of wood covered with sheet iron, will cross the building at five points, and fireproof walls will also inclose the stairways and elevator shafts, as shown by the plan, Fig. 7. This plan FIG. 7.—SECOND FLOOR PLAN OF BULKHEAD SHED. shows the points where the pier sheds connect with the bulkhead building, and opposite these points on the shore side of the building the gallery extensions of the second floor, which are connected with the ground and also with the sid& bays of the roof by stairways. As shown by Fig. 4, there will be a hood or awning along the shore side of the building. The ground floor of the bulkhead building will be used for storing the incoming and outgoing cargo, which will be removed and delivered by trucks. As will be seen by Fig. 1, a large yard is provided between Water St. and the building for the accommodation of carriages and trucks. The second floor of the building will be devoted wholly to the passenger traffic, the baggage rooms, waiting rooms and offices being all on this floor. PIERS AND PIER SHEDS. As shown by Fig. 1, three piers will extend out into the river from the bulkhead building, which will be known as piers No. 1, No. 2 and No. 3, pier No. 1 being the northernmost. These piers will be,.respectively, 80 x 905.46 ft., 80 x 889 3/4 ft., and 90 x 869.27 ft. The piers are to be pile structures, with the piles spaced 6 ft. c. to c. in transverse rows, 9 ft. apart, except at the outer end, where for a distance of about 300 ft. the piles are to be spaced 3 ft. c. to c., and the five outer rows made double. The part sketch plan, Fig. 8, shows Fig. 8.— Sketch Plan of Piling for Piers. the two arrangements. Ordinarily the piles used will be ordinary 85-ft. to 90-ft. piles, 14 ins. in diameter at the point of cutoff and 6 ins. in diameter at the points, but at certain points, as indicated in Fig 8, lagged piles will be employed. Details of one of these lagged piles are shown by Fig. 9. The outer ends of the piers are to be built with round corners, as shown by the detail drawings in Fig. 10. A plan of the platform framing is shown by Fig. 11, and Figs. 12 and 13 show typical sections across the pier. The caps, stringers, backing logs, sills and subsills will be 12 x 12-in. timbers, and the deck planking will be 4 ins. thick. The deck planking, sills, subsills and the several courses of timber laid solid at the sides above and below the deck will be creosoted. The close rows oi piles toward the end of the pier will be braced with 4-in. sheathing on each side from low water up to the side cap. This construction is shown by Fig. 12. The bracing of the remaining rows of piles consists of a double horizontal A-bracing, with the side piles further braced with diagonal sheathing above the A-braces, as shown by Fig. 13. At the extreme outer end of the pier, where the five outer rows of piles are driven double, the transverse bracing will be horizontal lagging, and wales, as shown by Fig. 14, and the rows of piles under the cross partitions or fire walls (A) of the pier shed, will be inclosed on both sides with .vertical sheathing arranged as shown by Fig. 15. Fig. 16 shows details of the framing at points where derrick masts are located, and Fig. 17 shows details of the mooring posts and their foundations. Finally, Fig. 18 shows the method of inclosing the sides and outer end of the pier. The outside oak sheathing is grooved for 2 X 4-in. yellow pine splines. The details shown in Figs. 8 to 18, inclusive, are for pier No. 3, but the other two piers will be exactly similar in construction, except that the framing of pier No. 2 will provide for carrying a 3-ft. 4-in. sewer its entire length at the center and below the platform. This sewer extension will be built of 4-in. creosoted staves with-galvanized iron clamps. Each pier will be surmounted by a two-story steel frame pier shed occupying the entire width of the pier, with the exception of 4 ft. on each side. The sheds for piers No. 2 and No. 3 wiil have two floors, as shown by Fig. 19, but that for pier No. 1 will have at first but one floor, as shoWn by Fig. 20. For piers Nos. 2 and 3 the shed construction will consist of two wall columns carrying a plate roof girder; the roof girder supporting a monitor ventilator and having suspenders Fig. 11.— Sketch Plan Showing Platform Timbering for Piers. which, with the wall columns, support the second floor girders. Fig. 21 shows a section of one of the wall columns with its fireproofing. The bents for all of the piers will be spaced 18 ft. apart. The side walls between columns will consist of wood sheathing covered with tin, and the roofs will consists of 3-in. tongued and grooved sheathing covered with felt and gravel roofing. The second floor will consist of 3-in. grooved flooring of yellow pine, covered with three-ply roofing felt and asphalt -roofing cement to prevent the passage of water, on top of which comes a thickness of asbestos felt and then a wearing floor or surface of %-in. x 2%-in., tongued and grooved maple flooring. The ground floor of the sheds will consist of a 6-in. layer of concrete, in which will be bedded 4 x 6-in. oak nailing strips for fastening a 2 x 8-in. oak flooring. As a protection against fire the undersides of the floor and roof of the pier sheds will have No. 22 gage galvanized corrugated iron arches sprung between the bottom flanges of the floor beams, and filled with cinder concrete, with enough cement to prevent the formation of dust and the disintegration of the filling. As a further protection in case of fire each pier shed will be divided into three nearly equal portions by two transverse partitions or fire-walls. These walls will consist of three thicknesses ol tongued and grooved boards of a maximum width of 4% ins., covered on each side with small roofing teme plates, about 10 x 14 ins., locked and blind-nailed and painted on both sides before being applied. The openings through these cross walls for the passage of freight and passengers, two on each floor, and the openings in the side walls are to be closed with tin-covered wooden doors of the standard underwriters' type. All windows, including skylights, will have iron sash and be glazed with wire-glass. FIRE APPLIANCES. For protection in case of fire the underside of the roof and the underside of the floors above the first floor in both the bulkhead shed and the pier sheds will be fitted with automatic sprinklers, on the dry pipe system, of a construction approved by the Board of New York Fire Underwriters. In addition a line of 6-in. water pipe will be run along each side of each pier, with hose connections and 50-ft. reels of hose located every 50 ft. Finally, the entire bulkhead and pier structure will be provided with the multiphase cable system of automatic alarm in case of fire, with loose coils of the same cable to be laid over stored merchandise. MISCELLANEOUS. The sides of the piers will be provided at intervals with derrick masts 61 ft. in height, 15 in. in diameter at the heel, and 14 ins. in diameter at the top band, fitted with steel span wires and back stays for handling freight. At intervals of 90 ft. cast-iron mooring posts, of the construction shown by Fig. 18, will be provided. The various structures are to be provided with gutters, and suitable finishing and finally painted. All stairways are to be of fireproof construction, and provided with coverings. [end article] [two-page fold-out plate] Supplement to Engineering News, January 3, 1901 [listed clockwise from top left] Figure 10. Details of Corner Framing at Ends of Piers. Figure 4. Transverse Section of Bulhead Shed and Foundations Figure 19. Transverse Section of Sheds for Piers Nos. 2 and 3 Figure 14. Longitudinal Section Near Outer End of Pier Showing Double Piles and Bracing Figure 15. Longitudinal Section Showing Piling and Bracing Under Fire Walls Figure 13. Standard Transverse Bracing for Piles, Space 6 Ft. on Centers Figure 12. Sheathed Transverse Bracing for Piles Toward End of Pier, Space 3 Ft. on Centers Figure 18. Elevations Showing Outside Sheathing for Piers Figure 2. Typical Transverse Section of Bulkhead Wall and Foundations Figure 9. Details of Pile Reenforced by Lagging Timbers Figure 17. Deatails of Mooring Posts [Bollard] and Fastenings Figure 16. Details of Derrick Mast Foundation Figure 6. Section of Interior Column for Bulkhead Shed Figure 21. Wall Column for Pier Sheds Figure 5. Sections Showing details of Floor Construction in Bulkhead Shed [end plate] Status: OK Status By: dw Status Date: 2011-04-21