Collections Item Detail

Article: Coal Handling Plant at the Hoboken Terminal of the Lackawanna R.R. The Engineering Record, Vol. 52, No. 24; Dec. 9, 1905.

2012.007.0054

2012.007

Lukacs, Claire

Gift

Museum Collections. Gift of a Friend of the Museum.

1905 - 1905

Date(s) Created: 1905 Date(s): 1905

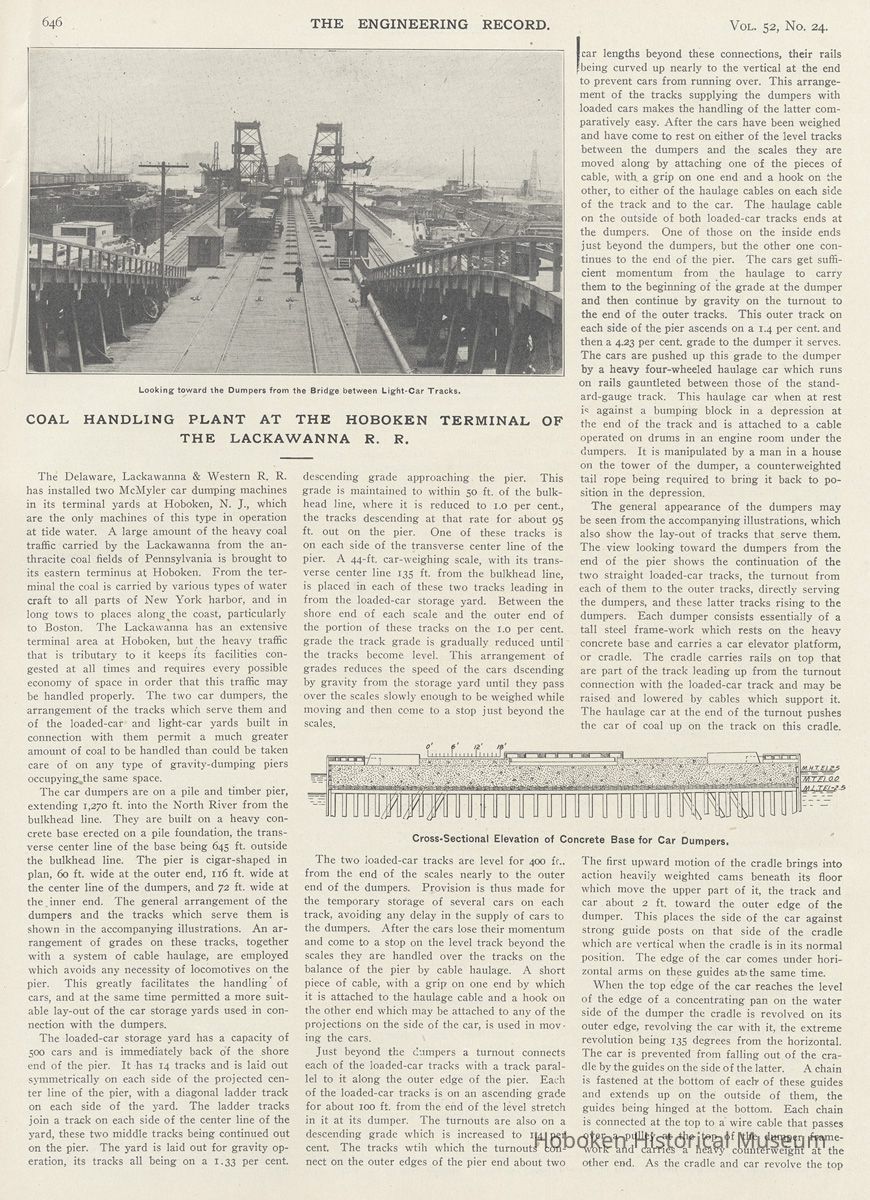

Notes: Archives 2012.007.0054. The Engineering Record, Volume 52, No. 24, Dec. 9, 1905, pages 646-648. Full text of this article only. [caption for photo above article title] Looking toward the Dumpers from the Bridge between Light-Car Tracks. COAL HANDLING PLANT AT THE HOBOKEN TERMINAL OF THE LACKAWANNA R. R. The Delaware, Lackawanna & Western R. R. has installed two McMyler car dumping machines in its terminal yards at Hoboken, N. J., which are the only machines of this type in operation at tide water. A large amount of the heavy coal traffic carried by the Lackawanna from the anthracite coal fields of Pennsylvania is brought to its eastern terminus at Hoboken. From the terminal the coal is carried by various types of water craft to all parts of New York harbor, and in long tows to places along_the coast, particularly to Boston. The Lackawanna has an extensive terminal area at Hoboken, but the heavy traffic that is tributary to it keeps its facilities congested at all times and requires every possible economy of space in order that this traffic may be handled properly. The two car dumpers, the arrangement of the tracks which serve them and of the loaded-car and light-car yards built in connection with them permit a much greater amount of coal to be handled than could be taken care of on any type of gravity-dumping piers occupying the same space. The car dumpers are on a pile and timber pier, extending 1,270 ft. into the North River from the bulkhead line. They are built on a heavy concrete base erected on a pile foundation, the transverse center line of the base being 645 ft. outside the bulkhead line. The pier is cigar-shaped in plan, 60 ft. wide at the outer end, 116 ft. wide at the center line of the dumpers, and 72 ft. wide at the.inner end. The general arrangement of the dumpers and the tracks which serve them is shown in the accompanying illustrations. An arrangement of grades on these tracks, together with a system of cable haulage, are employed which avoids any necessity of locomotives on the pier. This greatly facilitates the handling' of cars, and at the same time permitted a more suitable lay-out of the car storage yards used in connection with the dumpers. The loaded-car storage yard has a capacity of 500 cars and is immediately back of the shore end of the pier. It has 14 tracks and is laid out symmetrically on each side of the projected center line of the pier, with a diagonal ladder track on each side of the yard. The ladder tracks join a track on each side of the center line of the yard, these two middle tracks being continued out on the pier. The yard is laid out for gravity operation, its tracks all being on a 1.33 per cent descending grade approaching the pier. This grade is maintained to within 50 ft. of the bulkhead line, where it is reduced to 1.0 per cent., the tracks descending at that rate for about 95 ft. out on the pier. One of these tracks is on each side of the transverse center line of the pier. A 44-ft. car-weighing scale, with its transverse center line 135 ft. from the bulkhead line, is placed in each of these two tracks leading in from the loaded-car storage yard. Between the shore end of each scale and the outer end of the portion of these tracks on the 1.0 per cent, grade the track grade is gradually reduced until the tracks become level. This arrangement of grades reduces the speed of the cars dscending by gravity from the storage yard until they pass over the scales slowly enough to be weighed while moving and then come to a stop just beyond the The two loaded-car tracks are level for 400 feet from the end of the scales nearly to the outer end of the dumpers. Provision is thus made for the temporary storage of several cars to each track, avoiding any delay in the supply of cars to the dumpers. After the cars lose their momentum and come to a stop on the level track beyond the scales they are handled over the tracks on the balance of the pier by cable haulage. A short piece of cable, with a grip on one end by which it is attached to the haulage cable and a hook on the other end which may be attached to any of the projections on the side of the car, is used in moving the cars. Just beyond the dumpers a turnout connects each of the loaded-car tracks with a track parallel to it along the outer edge of the pier. Each of the loaded-car tracks is on an ascending grade for about 100 ft. from the end of the level stretch in it at its dumper. The turnouts are also on a descending grade which is increased to 1.4 per cent. The tracks wtih which the turnouts connect on the outer edges of the pier end about two fear lengths beyond these connections, their rails (being curved up nearly to the vertical at the end to prevent cars from running over. This arrangement of the tracks supplying the dumpers with loaded cars makes the handling of the latter comparatively easy. After the cars have been weighed and have come to rest on either of the level tracks between the dumpers and the scales they are moved along by attaching one of the pieces of cable, with a grip on one end and a hook on the other, to either of the haulage cables on each side of the track and to the car. The haulage cable on the outside of both loaded-car tracks ends at the dumpers. One of those on the inside ends just beyond the dumpers, but the other one continues to the end of the pier. The cars get sufficient momentum from the haulage to carry them to the beginning of the grade at the dumper and then continue by gravity on the turnout to the end of the outer tracks. This outer track on each side of the pier ascends on a 1.4 per cent, and then a 4.23 per cent, grade to the dumper it serves. The cars are pushed up this grade to the dumper by a heavy four-wheeled haulage car which runs on rails gauntleted between those of the standard-gauge track. This haulage car when at rest is against a bumping block in a depression at the end of the track and is attached to a cable operated on drums in an engine room under the dumpers. It is manipulated by a man in a house on the tower of the dumper, a counterweighted tail rope being required to bring it back to position in the depression. The general appearance of the dumpers may be seen from the accompanying illustrations, which also show the lay-out of tracks that serve them. The view looking toward the dumpers from the end of the pier shows the continuation of the two straight loaded-car tracks, the turnout from each of them to the outer tracks, directly serving the dumpers, and these latter tracks rising to the dumpers. Each dumper consists essentially of a tall steel frame-work which rests on the heavy concrete base and carries a car elevator platform, or cradle. The cradle carries rails on top that are part of the track leading up from the turnout connection with the loaded-car track and may be raised and lowered by cables which support it. The haulage car at the end of the turnout pushes the car of coal up on the track on this cradle. [caption under diagram] Cross-Sectional Elevation of Concrete Base for Car Dumpers. The first upward motion of the cradle brings into action heavily weighted cams beneath its floor which move the upper part of it, the track and car about 2 ft. toward the outer edge of the dumper. This places the side of the car against strong guide posts on that side of the cradle which are vertical when the cradle is in its normal position. The edge of the car comes under horizontal arms on these guides at the same time. When the top edge of the car reaches the level of the edge of a concentrating pan on the water side of the dumper the cradle is revolved on its outer edge, revolving the car with it, the extreme revolution being 135 degrees from the horizontal. The car is prevented from falling out of the cradle by the guides on the side of the latter. A chain is fastened at the bottom of each- of these guides and extends up on the outside of them, the guides being hinged at the bottom. Each chain is connected at the top to a wire cable that passes over a pulley at the top of the dumper framework and carries a heavy counterweight at the other end. As the cradle and car revolve the top page 647 of the latter comes against the guides and throws them sufficiently out of the vertical plane to bring the counterweights in action. The concentrating pan is hinged at the edge along the dumper, where it is attached to the frame-work. It is supported at the outer end by an eight-part tackle rove with a wire cable with one end fastened to the top of the steel frame and the other end around a drum in the engine room. An adjustable screen is placed in the bottom of the pan, and beneath this screen is a screw conveyor which carries the screenings to a spout at one end. The rate at which the coal is dumped from the car depends on the amount the car is tipped, and is regulated according to the condition of the coal, that is, whether it is fine or coarse and wet or dry. The operation of the cradle and pan is controlled by an operator in the house on the frame-work, who regulates the rate of dumping so the coal may be properly screened and breakage prevented. The end of the concentrating pan may be raised and lowered by the tackle which supports it. A square, sheet-steel, telescopic discharge chute carried on the end of the pan may be varied in length to considerable extent. This chute is manipulated by an electric motor controlled by an operator who stands on a platform around the top of the chute and is in full view of the coal in the concentrating pan and that in the vessel. He can vary the position of the end of the discharge to suit the stage of the tide, the size of the vessel that is being loaded and the height of coal in the latter. In this way the drop of the coal from the car to the hold of the vessel is reduced The spout at the end of the screw conveyor under the screen in the concentrating pan is telescopic and changes length as the pan is raised and lowered. It is connected at the bottom to the boot of a bucket elevator, built by the Link Belt Machinery Co., the elevator discharging at the top into a storage pocket built beside the dumper. A weighing device is installed in this pocket, so the amount of screenings removed from [caption under photo] A Car Partially Turned Over in the Dumping Operation. the coal placed in a boat may be determined at once, and from this and the car weights the exact amount of coal put in the boat may be determined as soon as the last car consigned to it is dumped. The screenings pocket dumps into a car on-the track beneath it, or into a boat beside When the coal has all been dumped from a car the latter is righted in position again and the cradle lowered to the track level. The next loaded car pushes the empty car off the dumper and the dumping operation is repeated. The dumping of a car from the time it reaches the dumper until it leaves the latter requires on the average about 2 min. The dumper can handle all sizes and types of cars in service in the coast trade and has a capacity of handling a load of 160,000 lb., comprising a car and its contents. Under normal operating renditions each dumper handles about 600 tons an hour, but as high as 8,000 tons have been handled in 10 hr. by each machine. Two steam winches to each dumper greatly facilitate the handling of scows along the pier. The track on which the empty cars leave the dumper is laid on a i.o per cent, descending grade for 465 ft., the cars operating by gravity on it. A track scale, 44 ft. long, is placed with its transverse center line 125 ft. back from the end of this grade and the empty cars are weighed in passage. At the end of this descending grade the track begins to rise on a trestle until it is finally ascending on a 16 per cent, grade, the total length of the ascent being 145 ft. At the summit a descent is commenced on a grade which reduces from 2 to 1.33 per cent., and continues several hundred feet to a light-car storage yard. The light cars are hauled up the 16 per cent, grade by a four-wheeled haulage car, one on each track, which is operated the same as those which push the loaded cars to the dumpers. Each haulage car is in a depression under the track which it serves and beyond the track scale, where it remains until the light car has passed over it. It is attached to a cable on a drum in an engine room beneath the summit of the trestle. It is controlled by an operator in a house on a bridge between the trestles carrying the light-car tracks of the two dumpers, and spanning the two loaded-car tracks. The light-car tracks leading from both dumpers have the same arrangement. The one .from each machine discharges cars into a light-car storage yard, one of these yards being on each side of the loaded-car storage yard. One of the illustrations is a view looking from the bridge between light-car track trestles toward the dumpers and the outer end of the pier. It shows the two loaded-car tracks leading in from the storage yard, the track scale in each of these tracks and the cable haulage on each side of the tracks. The light-car tracks from the dumpers are shown on either side of the pier. The right-hand loaded-car track may be seen to be extended to a coal pocket at the end of the pier, its haulage cable also being extended. This coal pocket has a capacity of 1,800 tons and supplies fuel to boats in the harbor. An 8 x10 x 22-ft. steel hopper is placed beneath the track at the entrance to the pocket. The cars discharge into this hopper, which had to be made watertight, as its bottom is 1 ft. above mean high tide. A bucket elevator raises the coal from the hopper to a flight conveyor, which discharges it into various bins. The discharge spouts of the bins empty in weighing hoppers on wheels on a dolly track parallel to the sides of the building, the hopper discharging into the bunkers of the vessels. The drums of the cables of the haulage cars, those of the endless cables serving the loaded-car tracks and the operating machinery of the dumpers, with the exception of the electric motors on the spouts of the concentrating pans, are operated by steam engines. Steam is supplied through a 12-in. main by a boiler plant in a central brick station building at the shore end of the pier. This station contains four hand-fired, 256-h. p., water-tube Stirling boilers. An addition is being added to the station building and two mort boilers of the same size are being installed. A 500 and a 750-gal. fire pump is installed in an engine room adjoining the boiler room. These pumps furnish water for fire protection to the terminal yards and structure, and will be supplemented by the addition of other pumps. A storage bin is built under the light-car track next to the power house near the summit of the trestle carrying it at that point. An opening is made in the track structure so coal may be discharged from bottom-dump cars into the bin. One side of the latter is the side wall of the station building and doors connect it with the firing floor of the boiler room. The pier carrying the dumpers and the tracks serving them is built in 10 to 25 ft. of water. The bottom of the river is a soft silt to a depth of 60 to 130 ft., with a layer of sand and gravel underlying the silt. This condition, together with the peculiar shape of the pier and the heavy footing required for the dumpers, made the construction quite difficult. The pier contains 117 transverse pile bents, most of which are on 12-ft. centers. Owing to the differences in length of practically every bent, except those toward the outer end, and to the various grades in the tracks on the pier, most of the bents have different details, although a general method of construction was followed in building all of them. The two dumpers and their operating machinery are carried on a concrete base, 81.5x116 ft. 8 in. in plan and with an average thickness of 5 ft. This base is built as a monolith, without any reinforcement, and is laid directly on a tight timber floor placed on caps on piles. There are 1,080 piles under the floor, which are cut off at mean low tide and capped with 12x12-in. timbers on the transverse bents. Over the caps is laid the tight floor made up of 10x12 and 12x12-in. longitudinal timbers. The load on the base is about page 648 1,000 tons, largely concentrated on the legs of the dumpers toward its outer edges. The live loads on the base are such as to subject the concrete to considerable shock and vibration, but after two years of service no cracks have developed in it, The whole base has, however, settled perceptibly since it was built at gradually diminishing rates until settlement has now practically The plans for the pier on which the coal dumpers are built and the arrangement of the tracks which serve them were developed under the direction of Mr. L. Bush, chief engineer of the Delaware, Lackawanna & Western R. R., by Mr. Geo. T. Hand, assistant engineer. The pier was built under the immediate direction of Mr. J. E. Snell, Superintendent of buildings and docks of that railroad, and its operation is under his supervision.. The McMyler Mfg. Co. built both of the coal dumpers. One of them was installed by the Dodge Coal Storage Co., as eastern representative of that company. The other was installed by the McMyler Mfg. Co. [end article] [caption under photo] Looking Toward the Dumpers From the End of the Pier. Status: OK Status By: dw Status Date: 2012-03-22