Collections Item Detail

Article (H. & M.R.R.): The Beginning of Train Service Under the Hudson River at New York. In: The Engineering Record, V.57, N.9, Feb. 29, 1908

2013.001.0027

2013.001

Purchase

Purchase

Museum Collections.

1908 - 1908

Date(s) Created: 1908 Date(s): 1908

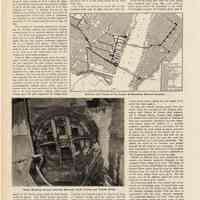

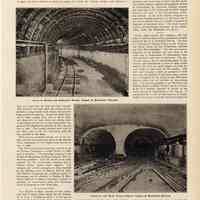

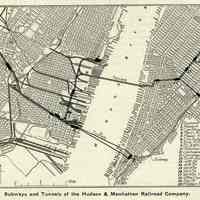

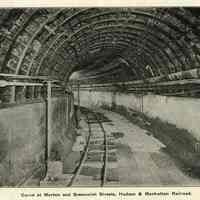

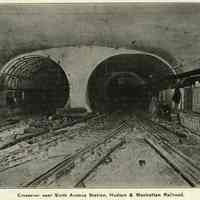

Notes: Archives 2013.001.0027 re Hudson & Manhattan Railroad ==== The Engineering Record, Vol. 57, No. 9, February 29, 1908, pages 249-251. ==== page 249, article starts in column 3 The Beginning of Train Service Under the Hudson River at New York. The formal opening of the Morton Street twin tunnels of the Hudson & Manhattan Railroad on Tuesday of this week was an event of more than ordinary interest to engineers as well as to the thousands of people who cross the river between Manhattan Island and the neighboring New Jersey cities. This new transportation line is not the first subaqueous railway into Manhattan, to be sure, for the tunnel under the Harlem River from the Bronx and the tunnel under the harbor from Brooklyn have been in service for some time. The Morton Street route has a special interest, nevertheless, as a long-needed link between New Jersey and Manhattan, which have lacked the bridge connections existing between the New York boroughs and have been forced to put up with ferries, which are slow and land their passengers in Manhattan at points inconveniently situated for making quick trips to many important business districts of the island. The opening of the line has an additional interest to the engineer, as it marks the successful completion of an enterprise that for many years proved beyond engineering and financial resources. The division of the Hudson & Manhattan Railroad opened this week between New York and Jersey City is the northern line shown on the map, with the extension on the New Jersey side to the Delaware, Lackawanna & Western Railroad station and on the New York side to Sixth Avenue and Nineteenth Street. While the tubes are operated by the Hudson & Manhattan Railroad Company, they were constructed by an allied corporation, the Hudson Companies. The land and subaqueous tunnels thus put into operation are but part of an extensive system of passenger subways and tunnels on both sides of the Hudson River, with approximately 18 miles of single tube, having connections with the Pennsylvania, Erie j and Lackawanna depots on the west bank of the Hudson and reaching northward in Manhattan to Thirty-third Street and Sixth Avenue. The system includes not-only the twin river tunnels at Morton Street, but also another pair of single-track tunnels extending from the Pennsylvania station in Jersey City to a large new terminal building at Cortlandt and Church Streets, in the lower end of Manhattan Island. Connections will be made between the new system and the New York Rapid Transit subway system at two points, one at Dey Street, by a foot passage to the Fulton Street subway station, and the other by twin tubes under Ninth Street to a point just north of the present Astor Place subway station. The extension westward in Jersey City from the river contemplates stations dt Summit Avenue and Newark Avenue, where the cars will come to the surface and run over the existing Pennsylvania tracks to Newark. The complete layout is clearly shown in the accompanying map. Work was started on the Morton Street tunnels in November, 1874, by the Hudson Tunnel Railroad Company, of which the late DeWitt C. Haskins was president and manager. The plans laid down by Mr. Haskins contemplated a two-track brick tunnel, but before the work had progressed very far a change to two tubes was decided upon. A brick shaft 30 ft. in inside diameter was sunk on the New Jersey side near the river bulkhead line and an opening cut through it to start the tunnel. Many difficulties were encountered and it was found that the sinking of the shaft had so disturbed the surrounding ground that it was too large an undertaking to start the full tunnel section at the shaft. At the suggestion of the late Chas [Charles]. B. Brush, a tube 6 ft. in diameter was therefore started and enlarged in funnel-shape as it progressed, ending in the full section, about 19 ft. in diameter, in a distance of 30 ft. From this point the two separate tunnels ==== page 250 were started. In addition to the difficulties experienced in the caving ground the regulation of the compressed air, which is said to have been first used for horizontal tunneling in this work, occasioned considerable difficulty. The original plans for a single tunnel contemplated a height of 24 ft. and a width of 26 ft.; when the plans were modified to provide for two tunnels, a height of 18 ft. in the clear and a width of 16 ft. was adopted for them. A detailed account of the difficulties encountered at this time was given in a communication from Capt. John F. Anderson, the originator of the Anderson or pilot system of tunneling, in The Engineering Record of Aug. 17, 189S. The method of tunneling consisted in advancing the heading without any protection against caving except the air pressure against the wall of silt. The lining was composed at first entirely of brick, but so much difficulty was found in confining the air that Captain Anderson suggested the use of flanged iron plates. Their purpose was to hold the air pressure until the brick lining could be built, and since their thickness was but in., they were not relied upon save for the temporary construction purpose. Early in 1880 an improvement upon the unprotected heading method of driving the tubes was put into operation, the pilot system, worked out by Captain Anderson, then superintendent of construction of the tunnel, being used. The pilot consisted of a tube from so to 60 ft. long, 6 ft. in diameter, the forward end of which projected some distance into the silt in advance of the heading, while the rear end was held centrally in the completed portion of the tunnel. It was made of interchangeable flanged plates which were removed from the rear and placed at the forward end as the work advanced. Heavy radial struts resting upon this pilot supported the flanged iron plates of the tunnel proper until the brick lining could be placed. This device proved successful in maintaining the grade of the tunnel, with which considerable difficulty had been experienced. About the time that the pilot was introduced it was decided to remove the temporary entrance from the shaft to the tunnels and merge the tunnels into one near the shaft. While the work was under way on July 21, 1880, a blow-out occurred, ---- [caption lower left photo] Shield Breaking through Concrete Bulkhead, Sixth Avenue and Twelfth Street. ---- in which twenty men were trapped in the tunnel and drowned. On account of financial difficulties work was stopped in 1882. About 2000 ft. of the north tube had been finished on the New Jersey side, 600 ft. of the south tunnel on the same side of the river and about 200 ft. of the north tunnel on the New York side. The work was allowed to stand idle in this condition until Aug. 12, 1889, when the work was resumed with English capital, S. Pearson & Sons, of England, having taken the contract, with Sir John Fowler and Sir Benjamin Baker as consulting engineers. The new owners abandoned masonry lining and substituted instead heavy cast iron flanged plates. The pilot system was also discarded and the shield method substituted; the methods of connecting the old and new work were described in this journal on April 12, 1890. It was in connection with this shield that E. W. Moir, who was in charge of the work for S. Pearson & Sons, devised his hydraulic erector for placing the heavy cast-iron plates. The apparatus was fully described in an article in The Engineering Record of Oct. 25, 1890. Work on the north tube from the New Jersey side continued until June, 1891, when lack of funds again caused the suspension of the work. The English company had finished about 1900 ft. ---- [caption for map upper right] Subways and Tunnels of the Hudson & Manhattan Railroad Company. ---- of iron-lined tunnel, making the total length of the north tube about 3900 ft. In 1902, the tunnels having passed into new hands, work was resumed by the Hudson Companies, with Charles M. Jacobs, chief engineer, and J. Vipond Davies, deputy chief engineer. The shield which had been used by S. Pearson & Sons was extensively remodeled, the most important change being the addition of a movable cantilever platform to afford protection for the men drilling the rock, which in places projected up above the bottom of the tunnel and had to be blasted out. A shield was also built for the south tunnel and since that date the work has been prosecuted to a successful conclusion. The shields for much of the distance were pushed through the silt without any excavation. A complete description of the shield and of the methods followed on much of the work were published in The Engineering Record of July 25, 1903. Shields of different sizes were used in the two tunnels, the interior minimum diameter of the completed tubes being 15 ft. 3 in. The depth of the bottom of the tunnel below the surface of the Hudson River varies from 60 to 90 ft., while the distance from the roof of the tunnel to the bed of the river ranges from 15 to 40 ft. For the greater part of the distance under the river the tubes are on about 30-ft. centers. In connection with the New Jersey end of the tunnels an interesting piece of construction was carried out in the Y's which join the tubes with the subways running parallel with the river to connections with the three railroad terminals. The connection between the river tubes and the north and south tracks has been made in both directions, and in order to avoid the grade crossings that would have resulted if this had been made in the ordinary way the tracks for traffic in different directions were placed on different levels 24 1/2 ft. apart vertically. This construction would have been very complicated in the soft wet ground. ==== page 251, column 1 more than 80 ft. below the surface, if it had been carried out by ordinary tunneling methods. A short section of the structure where the lines converge and intersect was, therefore, isolated from the rest for construction purposes and closed with a solid mass of masonry pierced horizontally by an upper and lower chamber in which the connections are made with the land and river tunnels. This structure was built upon the surface of the ground as a huge doublc-deck caisson, the material being reinforced concrete. It was five-sided, about 101 ft. long, varying from 23 1/2 to 46 ft. wide, and about 51 1/2 ft. high above the cutting edge. A description of this interesting construction was given in The Engineering Record of Sept. 29, and Oct. 6, 1906. Two similar caissons were used at the other ends of the Y's connecting with the lines parallel to the river. Views of the completed tunnels, one of the stations and the cars used, were given in the Current News Supplement of The Engineering Record on Jan. 11, 1908. The final construction work was carried on by the Hudson Companies, of which Walter G. Oakman is president. The operating company is the Hudson & Manhattan Railroad Company, Wm.[Willam] G. McAdoo, president. Chas.[Charles] M. Jacobs is the chief engineer for the construction company and J. Vipond Davies, deputy chief engineer. The financial part of the enterprise is being handled by the banking house of Harvey Fisk & Sons. The Hudson Companies has a paid-up capital of $21,000,000, and in addition to Hudson & Manhattan Railroad Company securities received in payment for construction, owns over $5,000,000 worth of property in New York City. [end] ---- [caption for upper left photo] Curve at Morton and Greenwich Streets, Hudson & Manhattan Railroad. ---- [caption for lower right photo] Crossover near Sixth Avenue Station, Hudson & Manhattan Railroad. ==== ==== Status: OK Status By: dw Status Date: 2013-08-29