Collections Item Detail

Article: The Two-Story Street Railway Terminal of the Public Service Railway, Hoboken, N.J. Engineering News, Vol. 63. No. 16, April 21, 1910.

2013.005.0075

2013.005

Lukacs, Claire

Gift

Museum Collections. Gift of a Friend of the Museum.

1910 - 1910

Date(s) Created: 1910 Date(s): 1910

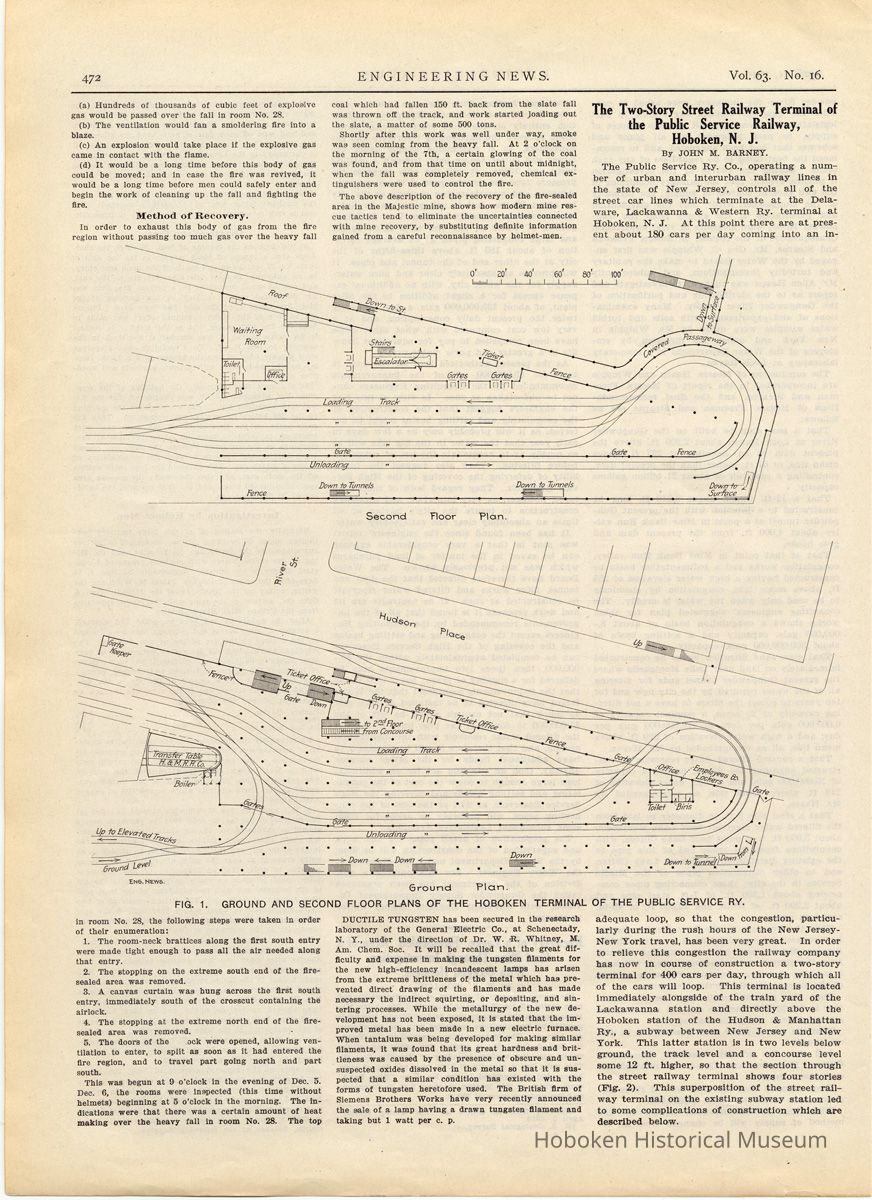

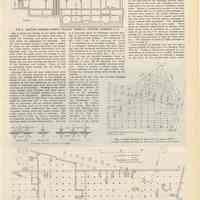

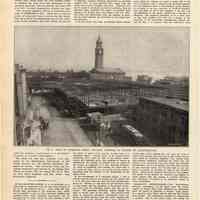

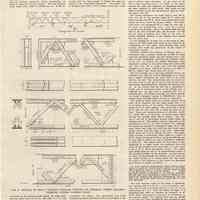

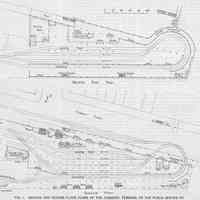

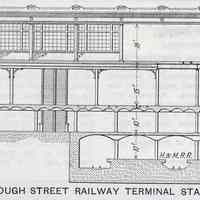

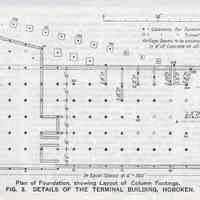

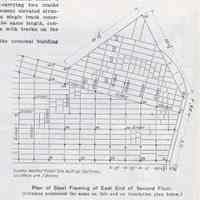

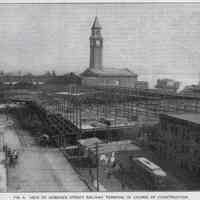

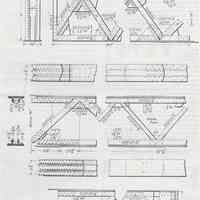

Notes: Archives 2013.005.0075 ==== ENGINEERING NEWS. Vol. 63. No. 16. April 21, 1910 pg 472 The Two-Story Street Railway Terminal of the Public Service Railway, Hoboken, N.J. By JOHN M. BARNEY. The Public Service Ry. Co., operating a number of urban and interurban railway lines in the state of New Jersey, controls all of the street car lines which terminate at the Delaware, Lackawanna & Western Ry. terminal at Hoboken, N. J. At this point there are at present about 180 cars per day coming into an inadequate loop, so that the congestion, particularly during the rush hours of the New Jersey-New York travel, has been very great. In order to relieve this congestion the railway company has now in course of construction a two-story terminal for 400 cars per day, through which all of the cars will loop. This terminal is located immediately alongside of the train yard of the Lackawanna station and directly above the Hoboken station of the Hudson & Manhattan Ry., a subway between New Jersey and New York. This latter station is in two levels below ground, the track level and a concourse level some 12 ft. higher, so that the section through the street railway terminal shows four stories (Fig. 2). This superposition of the street railway terminal on the existing subway station led to some complications of construction which are described below. ---- [caption illustration] Ground Plan. FIG. 1. GROUND AND SECOND FLOOR PLANS OF THE HOBOKEN TERMINAL OF THE PUBLIC SERVICE RY. ==== page 473 Fig. 1 shows the details of the street railway terminal. It contains two floors, into each of which the incoming cars enter on one track from which the passengers are unloaded. The car then proceeds around a loop into a ladder of tracks on the loading platform, and passes out, when loaded, without interfering with the incoming cars. On the ground floors the cars enter from the street level, but leading to the second floor an elevated structure has been built connecting with the existing elevated tracks upon which run the lines serving the district on top of the Palisades and beyond. There is also a connecting track between the two levels, as shown in Fig. 1. Although the cars all soon reach street level where the ordinary methods of collecting fares obtain, the loading platform of the station is fenced in and provided with ticket offices and choppers, so that the conductors do not have to attend to collecting fares from those who board the train at the terminal. Waiting rooms, newspaper stands, toilet facilities and other conveniences make the terminal similar to a railway station in its equipment. Entrance and exit is provided from and to both sides of the adjoining street by staircases and to the subway below both by staircases and an inclined escalator. The building itself is of steel and concrete construction with ornamental iron terra cotta and glass curtain walls and copper cornice. The entire ground floor is laid in concrete. The second floor is built up with a four-inch slab of reinforced concrete, two inches of sand filler, and four inches of wood block flooring. The roof is a four-inch layer of reinforced concrete resting on nine-inch channel purlins, supported by top chords of roof trusses. Its dimensions are 397 x 373 x 145 x 53 ft., following the outline of a trapezium as to the main building. There is a triangular extension from the main building, near the northeast end across Hudson Place. This extension is at the level of the second floor and measures approximately 115 X 90 x 90 ft. There is also an elevated extension from the west end of the building to Hudson Street—a distance of some 280 ft.—carrying two tracks and connecting with the present elevated structure. There is, further, a single track emergency extension of about the same length, connecting the elevated tracks with tracks on the surface. As shown by the cuts, the terminal building is, for the greater part, located directly above the Hoboken station of the Hudson & Manhattan R. R. Co. Now in the designing of the tunnel station the principle of the "floating foundation" was applied to the station as a whole. The soil is soft mud. Bearing power was taken at 1,000 lbs. per sq. ft. The construction of the roof of the tunnel does not permit of the placing of concentrated loads thereon except at column centers. On the other hand, the column spacing in the tunnels could not always be followed on account of the requirements of the trolley tracks on the ground floor of the new terminal building. A loop necessarily had to be provided at the east end of the building, another emergency loop at the west end, switches and turnouts had to be put in and car clearance looked after. Hence a considerable number of the first tier columns had to be placed over grillages to transmit their loads to the tunnel columns; and as the space between roof of tunnel and grade line was often very limited, shallow grillages of heavy section were necessary. The Bethlehem girder beams were useful in such cases. These cases of irregular distribution of column loads from above made it necessary in a number of cases to cut out the 7-in. cast-iron columns supporting the concourse ceiling, and replace them by heavier ones adequate to take the extra loading. The locations of some of these grillages is shown on Fig. 3. Other features of interest were the two heavy trussed girders of long span over Hudson Place (Fig. 5). Owing to limitations imposed by considerations of headroom over a public thoroughfare, and by the necessity of running a passage at the level of the second floor clear across ---- [caption top illustration] FIG. 2. SECTION THROUGH STREET RAILWAY TERMINAL STATION, HOBOKEN, N. J. ---- [caption left middle illustration] Sections showing Column Grillages ---- [caption right middle illustration] Plan of Steel Framing of East End of Second Floor. (Columns numbered the same on this and on foundation plan below.) ---- [caption bottom illustration] Plan of Foundation, showing Layout of Column Footings. FIG. 3. DETAILS OF THE TERMINAL BUILDING, HOBOKEN. ==== page 474 Hudson Place to connect with a stairway leading to the sidewalk there, it was necessary to fix at 6 ft. the depth of these girders of approximately 90 ft. span. These girders are calculated to carry the dead and live loads applying to the whole floor system, the wheel loads of the trolley cars, which pass out over Hudson Place in making the loop from the incoming to the outgoing platform, and in addition the roof load of a 9-ft. covered passageway around the loop. The moment diagram shows a maximum moment of 66,000,000 in.-lbs. They are, as will be noted, of unusually heavy section for the depth. Still, as a result of painstaking care in the treatment of the problem, they may safely be said to fulfill all ordinary requirements of a permanent structure in a public thoroughfare. The plans for this new terminal were prepared by the Engineering Department of the Public Service Ry., Mr. Martin Schrieber, Engineer in Charge. The structural work was designed, fabricated and erected by the Fagan Iron Works of Jersey City, for whom Mr. R. G. Foster was Chief Engineer and the writer was Structural Engineer. ----- [caption photo] FIG. 4. VIEW OF HOBOKEN STREET RAILWAY TERMINAL IN COURSE OF CONSTRUCTION ==== Page 475 (only content on this page related to article) Figure 5: DETAILS OF HEAVY TRUSSES CARRYING PORTION OF HOBOKEN STREET RAILWAY ACROSS HUDSON PLACE [thirteen small drawings] ==== ==== Status: OK Status By: dw Status Date: 2013-04-06